•Structural dynamics

•Ocular and other soft tissue biomechanics

•Testing of rate dependence of plastics, foam and biological Materials

•Impact safety

•Vibration testing and modal analysis

•Soy and other plant based engineering materials

•Elastic wave propagation

Impact Dynamics Laboratory

This laboratory is used for experimental research and education on the dynamic response and vibration of materials and structures. Tests are conducted in the facility focused on determining: (1) rate dependency, impact response, and energy absorption of materials; (2) constitutive relations; and (3) damping behavior and vibration modes. The laboratory is equipped with high-rate tensile and compression impact testing machines, vibration testing equipment, data processing devices, and a high-speed strain imaging system. Special emphasis is placed on research into the behavior of novel and complex materials, including foamed rigid polymers, shape memory alloys, ocular tissues, plant-fiber reinforced composites, soy foams and elastomers, and nano-materials.

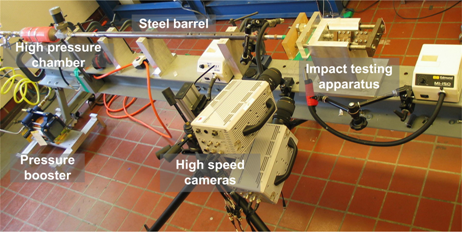

The photo below shows a direct measurement, high-rate testing apparatus specifically designed for low impedance materials.

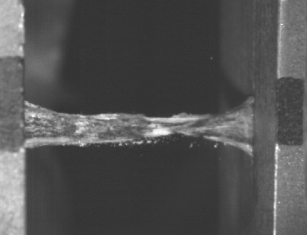

The sequence of video captures below shows a bovine sclera specimen deforming in tension at 57 strain/s. These images were captured at 10,000 frames per second. The left image shows the un-deformed specimen. In the center image the specimen has deformed to about 20% strain and the right image shows the failing specimen. Measurements accompanying the test reveal the material's mechanical rate dependence and failure characteristics. Understanding how ocular tissue dynamically responds to load can aid research on eye diseases such as glaucoma and keratoconus, and can lead to improved ocular protective gear.

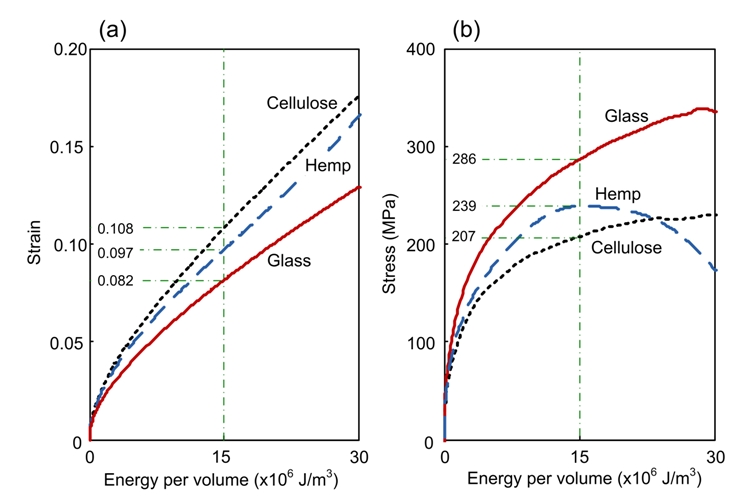

Experiments are also conducted in the laboratory to determine the energy dissipation characteristics of materials during high rate impact events. The figures below show strain and stress vs. dissipated energy per unit volume during material deformation at 2000 strain/s. In this case natural fiber reinforced materials (hemp and cellulose) are compared to a traditional glass fiber reinforced material. The curves show that energy is dissipated by the hemp and cellulose composites at lower stress and greater strain than the glass fiber composite. The goal of an impact safety material is to dissipate (or "absorb") a given amount of impact energy at as low stress as possible since the impacting body will be subjected to this stress. An ongoing research project is centered on determining the micro-structural features in materials responsible for good energy dissipation characteristics, and to capture those features in mathematical models of the materials.